| Tosoh Quartz, Inc. expends much time and effort to research the market and develop tools and processes to stay abreast of the present & future needs of our customers. We also use audits, such as ISO, vendor, and SSQA, to continually and objectively evaluate and upgrade all phases of operations.

|

| Even before the manufacturing process begins, all parts are reviewed by a multi-disciplined team for manufacturability. This can include FMEA & DOE, thus ensuring Tosoh Quartz the ability to meet and exceed customers' expectations, both explicit and implied.

The first step of this process is to design and build jigs & fixtures to assure process control and repeatability during manufacturing. This is all accomplished completely within Tosoh Quartz, with a fully staffed and equipped machine shop. |

|

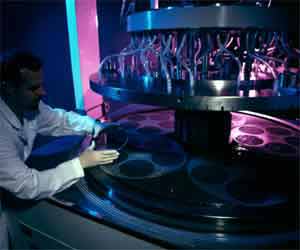

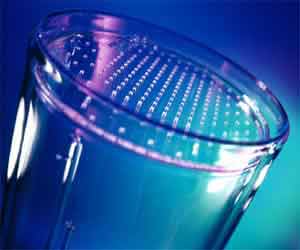

| Tosoh Quartz is a vertically integrated manufacturing site. The beginning of this process is the generation of solid components from bulk ingots (or boules). Tosoh Quartz has full capability to core drill, machine, lap, and polish complex shapes and features to customer specifications. |

All components are meticulously cleaned before processing, to insure the highest possible level of purity is maintained. Each item produced (both sub-assemblies and final products) has its own individual documented routing to insure complete control throughout the manufacturing process. Included in this route are in-process inspection steps to verify quality at critical steps of the manufacturing process. Products are tracked throughout the process by bar-coded job travelers to insure up to date, accurate reporting of each step of manufacturing in the shop.

|  |

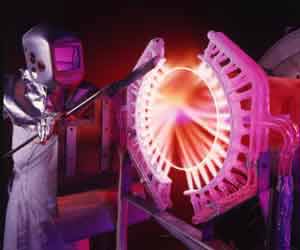

| Tosoh Quartz employs the most advanced manufacturing tools & techniques available. One of the most important includes using quartz burners, which allows the purity levels of the raw material to be maintained by reducing any possibility of metal contamination. Another is Tosoh Quartz's CADCAM capabilities, which allows complex designs to go from the computer directly to the CNC machining centers.

All manufacturing employees go through extensive training and cross-training. In addition to process training, other topics covered include quality and safety. This training is constantly updated as the newest manufacturing techniques and designs are developed.

|

Tosoh Quartz consistently takes on the most difficult items to manufacture, and is able to maintain the tightest tolerances in the industry. Much of the reason Tosoh Quartz can do this is the innovative approach to manufacturing. If a tool or piece of equipment that is needed doesn't exist, we design and build to our own high standards. This is evident throughout the factory, as much of the tools and equipment are specially designed by Tosoh Quartz. to fulfill the needs of manufacturing. Each tool or piece of equipment is initially certified by rigorous procedures before use. But the control doesn't stop there.

|

|

| All items manufactured are subjected to quality checks throughout the manufacturing cycle. Tosoh Quartz employs the most sophisticated and accurate tools and instruments to verify process control. Statistical controls are also set up at critical process steps to monitor manufacturing conditions.

Tosoh Quartz manufactures to each customer's specifications. In the absence of this, Tosoh Quartz has developed its own specifications which are among the most stringent in the industry.

The final result is the delivery of products that meet or exceed our customers' expectations. |